Top Advantages of Automated Packaging for Businesses in 2023

In the rapidly evolving landscape of 2023, businesses are increasingly turning to innovative solutions to enhance efficiency and competitiveness. One such advancement that has gained significant traction is automated packaging. This technology revolutionizes the way products are packaged, offering a multitude of benefits that cater to the needs of modern enterprises. As companies face escalating demands for speed and cost-effectiveness, automated packaging stands out as a game-changer.

The integration of automated packaging systems not only streamlines operations but also minimizes labor costs and reduces human error. With machines capable of performing complex packaging tasks at unprecedented speeds, businesses can achieve higher throughput while maintaining consistent quality. Additionally, automated packaging allows for greater flexibility in packaging designs and sizes, accommodating a wide range of products. As sustainability becomes a vital consideration in consumer choices, automated packaging can also facilitate the use of eco-friendly materials, aligning production processes with environmental goals.

In conclusion, the adoption of automated packaging presents significant advantages for businesses in 2023, positioning them to meet current market demands while preparing for future challenges. By embracing this technology, companies can enhance operational efficiency, reduce costs, and ultimately improve customer satisfaction through faster and more reliable packaging solutions.

Key Efficiency Gains from Automated Packaging Systems

In 2023, businesses are increasingly turning to automated packaging systems to drive efficiency gains and optimize their operations. According to a report by the Freedonia Group, the global market for automated packaging solutions is expected to grow by 4.5% annually, reaching over $29 billion by 2025. This growth is fueled by the demand for faster production cycles and the need to reduce labor costs. Automated packaging not only enhances speed but also improves precision, minimizing material waste and increasing shelf-life through better sealing methods.

One of the key efficiency gains from leveraging automated packaging is the significant reduction in labor costs. A study from the Association for Packaging and Processing Technologies suggests that companies using automated systems can cut their labor expenses by up to 20%. Furthermore, automation allows for 24/7 operation, maximizing productivity and meeting consumer demand without the constraints of manual labor shifts. By streamlining processes, businesses can reduce product spoilage and maintain high standards of quality.

**Tips:** When considering the transition to automated packaging, assess your current production processes to identify inefficiencies. Start with incremental automation for specific tasks before fully integrating into your operations. Also, keep an eye on ongoing training for your workforce, as skilled operators are crucial for maximizing the benefits of these advanced systems. Investing in technology that offers scalability can future-proof your packaging solutions, ensuring adaptability to evolving market trends.

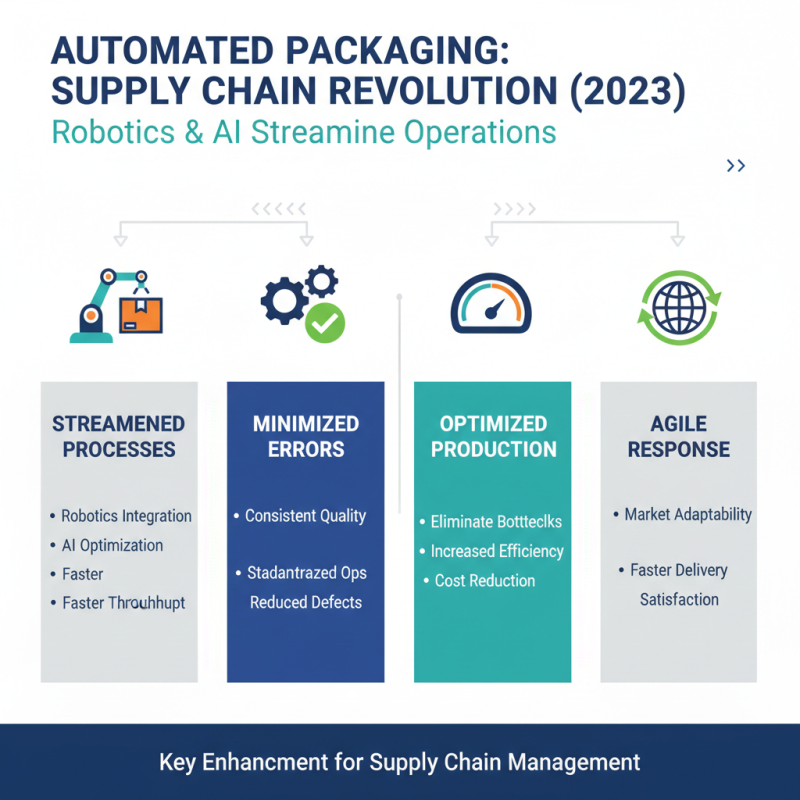

Top Advantages of Automated Packaging for Businesses in 2023

This chart illustrates the key advantages of automated packaging systems for businesses in 2023, highlighting increased efficiency, cost reduction, improved accuracy, enhanced safety, and faster production processes.

Cost Reduction Benefits of Automated Packaging Solutions

The cost reduction benefits of automated packaging solutions are becoming increasingly evident for businesses in 2023. As companies face rising operational costs and labor shortages, automating the packaging process offers a streamlined approach to cut expenses. By reducing the reliance on manual labor, businesses can lower wage costs, minimize errors, and reduce the need for extensive training programs.

Automation not only speeds up production times but also ensures consistent quality, which can lead to fewer returns and customer complaints, further enhancing cost efficiency.

Moreover, automated packaging solutions often utilize advanced technology that optimizes material usage. This results in less waste, lowering procurement costs for packaging materials. Businesses can also benefit from bulk purchasing, as automated systems typically require specific types of materials that may be bought in larger quantities, leading to significant cost savings. Additionally, the agility of automated systems allows businesses to adapt quickly to market changes, ensuring they can respond to demands without incurring excess labor or resource costs.

By investing in automated packaging, companies can create a more sustainable and profitable operation.

Enhancing Product Consistency with Automation in Packaging

In today's highly competitive market, maintaining product consistency is essential for businesses looking to establish strong brand loyalty and customer satisfaction. Automated packaging offers a solution that significantly enhances this consistency through precise and repeatable processes. By integrating advanced automation technologies, companies can ensure that each package meets specific quality standards without variation. This not only reduces the likelihood of errors but also provides customers with a reliable experience every time they purchase a product.

Furthermore, automated packaging systems are designed to adapt to varying production speeds and product types while still delivering uniform results. This flexibility allows businesses to maintain high throughput without sacrificing quality. With features such as real-time monitoring and error detection, automated systems can quickly identify and correct deviations in the packaging process, further protecting product integrity. As a result, companies can focus on expanding their operations, knowing that their commitment to quality remains uncompromised through the use of automation.

Improving Supply Chain Management through Automated Packaging

In 2023, automated packaging has emerged as a pivotal enhancement for improving supply chain management. By integrating advanced technologies such as robotics and artificial intelligence, businesses can significantly streamline their packaging processes. This automation minimizes human error and standardizes operations, leading to more consistent product quality. As a result, companies can optimize their production lines, reduce bottlenecks, and respond more agilely to market demands.

Moreover, automated packaging systems facilitate real-time tracking and inventory management, which are crucial for maintaining an efficient supply chain. With enhanced visibility into packaging operations, businesses can better anticipate stock levels and streamline logistics. This leads to reduced lead times and improved customer satisfaction as products reach consumers faster and with greater reliability. Overall, the shift towards automated packaging not only boosts operational efficiency but also establishes a more resilient and flexible supply chain.

Sustainability Advantages of Automated Packaging Technologies

In 2023, automated packaging technologies are revolutionizing the sustainability landscape for businesses. A report from Smithers forecasts that the global automated packaging market will reach $71 billion by 2026, driven largely by advancements that optimize material use. These technologies allow for precise utilization of packaging materials, reducing waste and promoting a circular economy. Companies can cut down on excess packaging while still maintaining product protection—a dual benefit that is essential in today's environmentally conscious market.

Moreover, automated systems enhance the efficiency of recycling processes. According to a study by McKinsey, around 30% of packaging waste could be eliminated through the application of smart packaging solutions. Automated packaging not only minimizes the volume of materials used but also incorporates recyclable materials that can be easily processed. This shift not only alleviates the burden on landfills but also empowers businesses to contribute to a more sustainable future, aligning their operations with increasing consumer preferences for eco-friendly practices. As the demand for sustainable packaging solutions grows, businesses that invest in automated technologies will find themselves at a competitive advantage while minimizing their environmental footprint.

Related Posts

-

10 Best Automated Packaging Solutions for Streamlining Your Business

-

Unlocking the Future of Packaging Automation with Digital Innovations

-

7 Essential Tips to Optimize Your Tray Sealer Packaging Machine Efficiency

-

How to Optimize Your Production Line with a Tray Sealer Packaging Machine

-

Revolutionizing Efficiency: The Future of Packaging Automation in Modern Manufacturing

-

How to Choose the Best Plastic Tray Sealing Machine for Your Business