10 Best Automated Packaging Solutions for Streamlining Your Business

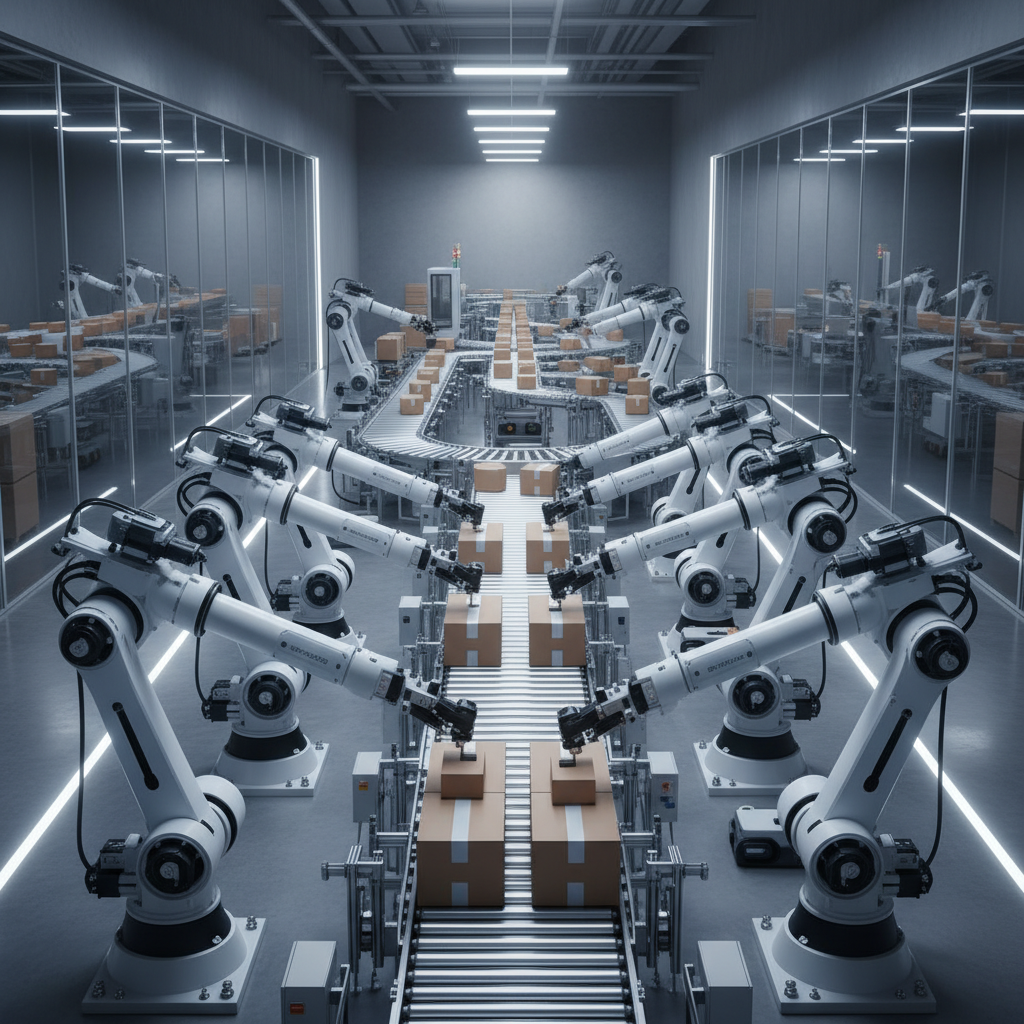

In today’s fast-paced business environment, efficiency and innovation are key drivers of success, particularly in the realm of operations and supply chain management.

Automated packaging solutions have emerged as a transformative force for companies looking to streamline their processes and enhance productivity. As we look forward to 2025, the significance of automated packaging will only grow, with advancements in technology offering businesses unprecedented opportunities to optimize their packaging methods.

Automated packaging solutions have emerged as a transformative force for companies looking to streamline their processes and enhance productivity. As we look forward to 2025, the significance of automated packaging will only grow, with advancements in technology offering businesses unprecedented opportunities to optimize their packaging methods.

This article will explore the "Top 5" automated packaging solutions poised to redefine industry standards in the coming years. These solutions not only contribute to cost savings but also improve accuracy and speed in packaging processes, catering to the increasing demand for customizable and scalable operations. By integrating automated packaging systems, companies can reduce labor costs, minimize waste, and ultimately deliver a superior product to their customers.

As we delve into the best options available, we will highlight key features and benefits of each solution, providing insights into how these innovations can be leveraged to boost operational efficiency and maintain a competitive edge in the market.

Innovative Automated Packaging Technologies to Enhance Efficiency

The packaging machinery industry plays a crucial role in automating and enhancing packaging processes across various sectors, including food, pharmaceuticals, and consumer goods. With advancements in technology, businesses are increasingly adopting innovative automated packaging solutions to improve efficiency and sustainability. This shift not only streamlines operations but can generate significant economic benefits, totaling approximately 90 million yuan for companies that implement these technologies.

Recent developments in automated packaging have been showcased at international exhibitions, illuminating the competitive landscape of fresh produce supply chains. Additionally, the rapid growth of artificial intelligence and sensor technologies in packaging signifies a future-oriented approach, as the global AI packaging market is projected to grow from $2.4 billion in 2024 to $6.2 billion by 2034, with a CAGR of 10.1%. These trends highlight the packaging industry's ongoing transformation in response to the demands for higher efficiency and improved supply chain transparency.

Automated Packaging Solutions Efficiency Comparison

This chart compares the efficiency percentages of various automated packaging solutions, showcasing how each solution enhances business operations through improved automation in packaging processes.

Key Features of Leading Automated Packaging Solutions

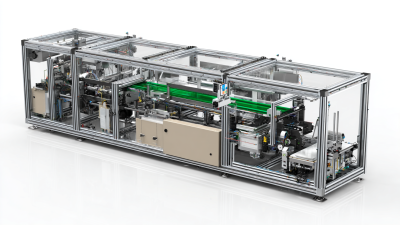

Automated packaging solutions have become essential for businesses aiming to enhance efficiency and reduce operational costs. The key features of leading automated packaging systems often revolve around their adaptability to various materials such as polyethylene (PE) and polypropylene (PP). These solutions can accommodate different production methods, including injection molding, film and sheet production, and blow molding. The versatility in applications allows businesses to tailor their packaging processes to meet specific product requirements, optimizing both workflow and material usage.

Automated packaging solutions have become essential for businesses aiming to enhance efficiency and reduce operational costs. The key features of leading automated packaging systems often revolve around their adaptability to various materials such as polyethylene (PE) and polypropylene (PP). These solutions can accommodate different production methods, including injection molding, film and sheet production, and blow molding. The versatility in applications allows businesses to tailor their packaging processes to meet specific product requirements, optimizing both workflow and material usage.

Incorporating advanced technologies, automated packaging solutions streamline processes by integrating real-time analytics and monitoring systems. This enables companies to track production rates, minimize waste, and maintain quality control throughout the packaging cycle. By leveraging these sophisticated features, businesses can not only speed up their packaging operations but also ensure consistency and reliability in their output. The combination of robust material compatibility and innovative processing techniques positions automated packaging solutions as a critical component for any modern business aiming to stay competitive in a fast-evolving market.

Comparative Analysis of Cost-Effectiveness for Packaging Systems

In today's fast-paced market, selecting the right automated packaging solutions can significantly impact a company's cost efficiency. A report by Technavio indicates that the global automated packaging market is expected to grow by over 17% annually from 2023 to 2027. This growth reflects businesses' increasing demand for packaging systems that not only enhance productivity but also cut operational costs. Automated systems reduce labor expenses and error rates, which can lead to substantial savings. For example, integrating automated packaging can decrease packaging time by up to 50%, allowing for quicker turnarounds and improved profitability.

When analyzing the cost-effectiveness of various automated packaging systems, it's crucial to consider initial investments versus long-term savings. According to a study by Smithers Pira, companies that invest in automated packaging can recoup their costs within 2-3 years due to reduced labor and material waste. Moreover, implementing an automated process can lead to up to a 30% reduction in packaging material costs, as state-of-the-art technology optimizes box sizes and minimizes filler materials. Such insights are invaluable for businesses seeking to streamline operations while maximizing their return on investment in packaging solutions.

Real-World Success Stories: Businesses Transforming with Automation

The integration of automated packaging solutions has become a game-changer for many businesses aiming to enhance efficiency and reduce operational costs. One of the standout examples is a company that adopted a fully automated packaging line, leading to a remarkable 30% increase in throughput while minimizing labor costs. Their success story illustrates how automation can not only streamline processes but also significantly boost productivity.

The Gartner Application Innovation & Business Solutions Summit emphasized the importance of embracing digital transformation strategies for success. Among the 21 strategies highlighted, one key tip is to prioritize data analytics to continuously evaluate and improve packaging processes. By monitoring performance metrics, businesses can make data-driven decisions that enhance their automation systems.

Moreover, the rise of agentic AI showcases another layer of transformation in the packaging industry. Companies leveraging AI for autonomous task execution have reported drastic improvements in quality control and error reduction. A valuable tip here is to invest in AI tools that seamlessly integrate with existing systems, ensuring a cohesive workflow that capitalizes on both automation and intelligent insights for crafting a truly efficient packaging operation.

Future Trends in Automated Packaging Solutions for Businesses

The future of automated packaging solutions is poised for transformative advancements driven by emerging technologies and sustainability initiatives. As businesses seek to streamline operations and reduce costs, the integration of artificial intelligence and robotics in packaging processes is becoming increasingly prevalent. These technologies not only enhance productivity but also ensure precision in packaging, minimizing waste and improving overall efficiency.

Moreover, the logistics industry is witnessing a shift towards sustainable packaging solutions that align with global environmental goals. Innovations such as biodegradable materials and energy-efficient packaging systems are gaining momentum, allowing businesses to cater to eco-conscious consumers. Companies are also exploring last-mile delivery technologies that will redefine the packaging landscape, making it more cost-effective while maintaining service quality. As these trends evolve, automated packaging solutions will play a crucial role in shaping a more efficient and sustainable future for businesses.

Related Posts

-

7 Essential Tips for Choosing the Right Food Packaging Machine for Your Business

-

Innovative Packaging Systems Driving Sustainability in the Global Market

-

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs

-

How to Optimize Blister Thermoforming for Maximum Efficiency and Cost Savings in Packaging

-

Exploring the Benefits of Investing in a High Quality Plastic Tray Sealing Machine

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection