How to Choose the Best Blister Pack Heat Sealer for Your Packaging Needs

In the fast-evolving landscape of packaging technology, selecting the right blister pack heat sealer is crucial for manufacturers aiming to enhance product safety and extend shelf life. According to a recent market report by Smithers Pira, the global blister packaging market is projected to reach $10.54 billion by 2026, underscoring the growing reliance on efficient sealing solutions. As product integrity becomes increasingly vital, investing in a high-quality blister pack heat sealer can significantly impact operational efficiency and consumer satisfaction.

Renowned industry expert Dr. Emily Hart, who has over two decades of experience in packaging technologies, emphasizes the importance of choosing the right equipment: “The performance of a blister pack heat sealer can define the success of your packaging strategy. Each product has unique requirements, and understanding these is key to making an informed choice.” With innovations in materials and technology, the market offers a variety of heat sealers tailored to different packaging needs, making it essential for businesses to assess their specific requirements carefully. As we delve deeper into the process of selecting the best blister pack heat sealer, we will explore critical factors to consider, ensuring that manufacturers make choices that align with both their packaging goals and consumer demands.

Understanding Blister Pack Heat Sealers and Their Importance

Blister pack heat sealers play a crucial role in the packaging industry, ensuring that products are securely enclosed and protected from external factors. These machines use heat to melt a sealing film around a product, creating a tamper-resistant barrier that maintains the integrity of the items inside. Understanding the various types of heat sealers available is essential for businesses looking to optimize their packaging processes. Different models cater to various production volumes, materials, and product sizes, making it vital to choose the right one for specific packaging needs.

The importance of blister pack heat sealers extends beyond mere packaging; they contribute to product safety and shelf life. A reliable heat seal ensures that products remain uncontaminated and free from environmental damage, which is especially critical for pharmaceuticals and food items. Moreover, effective sealing can enhance customer satisfaction by providing a hassle-free experience when opening products. Therefore, investing in the right blister pack heat sealer not only improves operational efficiency but also adds value to the product by maintaining its quality and safety for the consumer.

How to Choose the Best Blister Pack Heat Sealer for Your Packaging Needs

| Feature | Description | Importance |

|---|---|---|

| Heating Method | Different methods include direct heating, induction heating, and hot air. | Determines the efficiency and suitability of sealing different materials. |

| Sealing Speed | Refers to how many packs can be sealed per minute. | Affects production capacity and overall efficiency. |

| Temperature Control | Ability to maintain consistent temperature settings. | Critical for ensuring a proper seal without damaging products. |

| Size Compatibility | Refers to the range of blister sizes the machine can handle. | Essential for versatility in packaging various products. |

| Ease of Use | User-friendly controls and setup processes. | Impact on training time and operational efficiency. |

| Durability | Longevity of the machine under regular use. | Reduces maintenance costs and downtime. |

| Cost | Initial purchase price and operating expenses. | Affects overall return on investment and budgeting. |

Key Features to Consider When Choosing a Heat Sealer

When selecting the best blister pack heat sealer for your packaging needs, there are several key features to consider that can greatly affect performance and efficiency. Firstly, take note of the sealing temperature range. A versatile heat sealer with adjustable temperature settings allows you to work with different materials, ensuring a secure seal without damaging the product. Additionally, the sealing time should be customizable to accommodate various packaging types, providing greater flexibility for your operation.

Another essential feature is the machine’s speed and capacity. If you are looking to streamline production and meet high demand, opt for a sealer that offers rapid sealing capabilities without compromising quality. A reliable heat sealer should also come with safety features, such as automatic shut-off and overheat protection, to ensure safe and efficient operation.

**Tips:** Before making a purchase, consider conducting a trial run with your specific materials to evaluate compatibility and performance. Moreover, opting for a heat sealer with easy maintenance and readily available replacement parts can save you time and reduce downtime in the long run. Lastly, customer support and warranty options can be crucial factors that provide peace of mind and assistance when needed.

Different Types of Blister Pack Heat Sealers Available

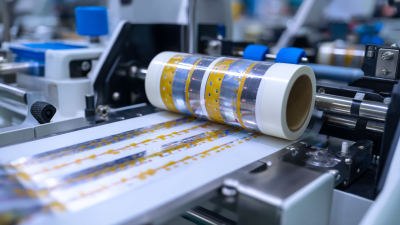

When considering the various types of blister pack heat sealers available, it's essential to understand the different technologies and configurations that cater to a range of packaging needs. Blister pack heat sealers can be categorized into rotary, inline, and manual models, each offering specific advantages depending on the production environment. For instance, rotary sealers are ideal for high-volume operations, providing efficiency and speed, while manual sealers are suitable for smaller batches and more flexible production lines.

Recent market reports indicate robust growth in related packaging sectors, with the thermoform packaging market projected to reach $65.6 billion by 2028. This growth highlights the increasing demand for efficient, reliable packaging solutions, including blister pack sealers, which are critical for ensuring product integrity and shelf life. Moreover, the global duct tape market is estimated to be worth USD 9.72 billion, showcasing the expansive need for versatile sealing options across various industries. These numbers underline the importance of investing in the right blister pack heat sealer to stay competitive in a rapidly evolving market landscape.

Assessing Your Packaging Needs for Optimal Heat Sealing

When assessing your packaging needs for optimal heat sealing, it's crucial to evaluate the peel performance of materials used in conjunction with specific sealing technologies. Recent studies highlight the importance of peel strength, which must be robust enough to prevent unintentional package openings under varying environmental conditions.

For instance, research indicates that optimizing peel performance can significantly enhance the integrity of packaging, thus prolonging product shelf life and ensuring safety throughout the supply chain.

The choice of materials is also vital, especially with the ongoing shift towards sustainable packaging solutions. Flexible fibre-based packaging has gained traction as industries look to reduce plastic waste. This aligns with findings that emphasize the role of seal integrity in flexible food packaging, where different seal bar geometries were found to affect the overall effectiveness of heat seals. Understanding these dynamics is essential for selecting a suitable heat sealer that aligns with the specific characteristics of the packaging materials and the intended product application.

Maintenance and Care Tips for Longevity of Heat Sealers

When investing in a blister pack heat sealer, maintaining its functionality is crucial for ensuring optimal performance and longevity. Regular maintenance can prolong the life of your equipment, which is vital given that the average lifespan of a heat sealer is approximately five to seven years, depending on usage, according to industry reports. Regular inspections of heating elements and sealing surfaces can prevent wear and ensure even heating, resulting in effective seals that meet industry standards.

To keep your heat sealers in top shape, consider incorporating routine cleaning into your maintenance schedule. Cleaning the heating elements with soft, non-abrasive materials can prevent the accumulation of residue that might affect the sealing quality. Furthermore, manufacturers often recommend lubricating moving parts and checking electrical connections as part of routine care. The introduction of proper training for operators can also significantly reduce operational errors, contributing to a decrease in maintenance needs and repair costs. By investing time in maintenance, businesses can save up to 30% on equipment replacement and service costs over time, making maintenance a critical aspect of managing blister pack packaging operations effectively.

Related Posts

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process

-

The Ultimate Guide to Choosing the Right Plastic Tray Sealing Machine for Your Business

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

7 Best Practices for Optimizing Your Blister Sealing Machine Efficiency

-

Maximizing Efficiency: How Blister Heat Sealing Machines Revolutionize Packaging Industries

-

How to Choose the Best Plastic Tray Sealing Machine for Your Business