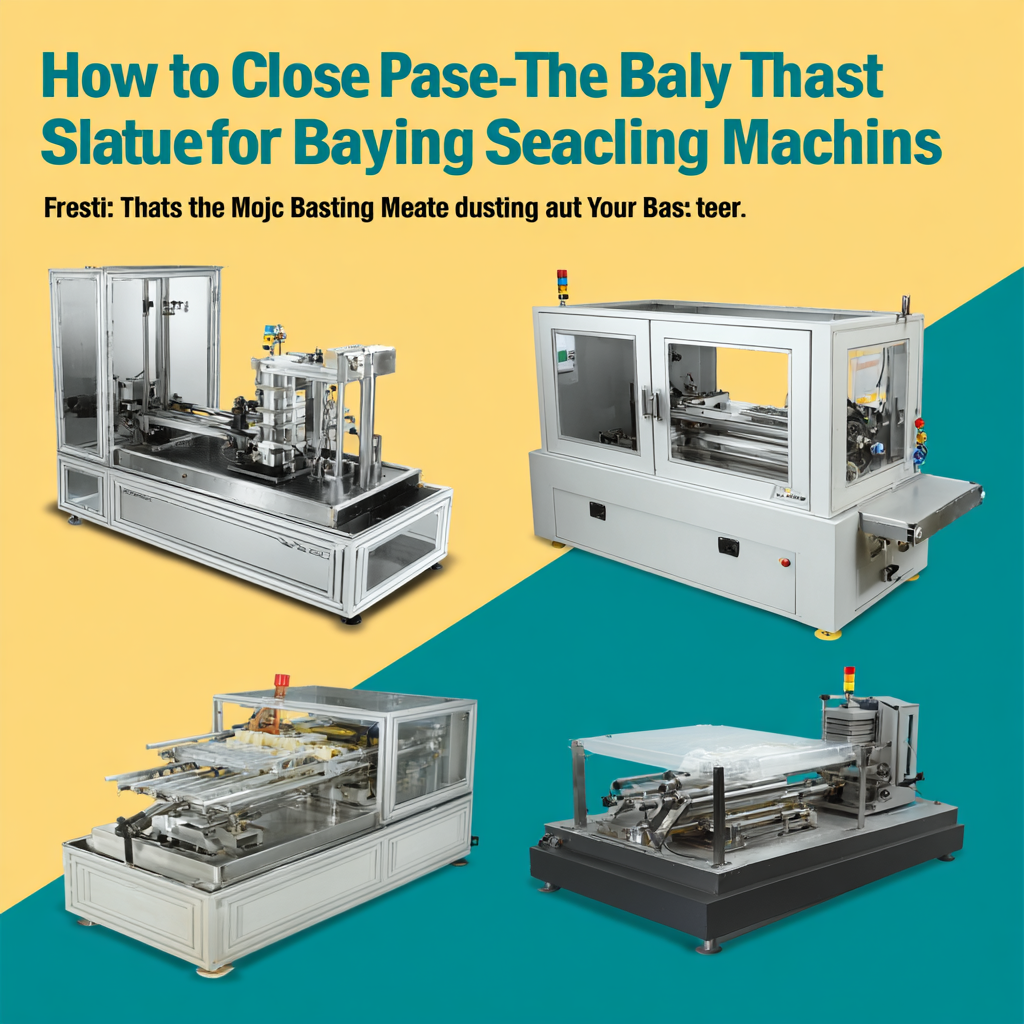

How to Choose the Best Plastic Tray Sealing Machine for Your Business

When it comes to enhancing the efficiency and presentation of your products, investing in the right equipment is crucial for the success of your business. Among the various tools available, a plastic tray sealing machine plays a vital role in packaging, ensuring both product preservation and visual appeal. However, choosing the best plastic tray sealing machine can be a daunting task given the myriad of options available in the market. It's essential to identify key factors that will impact your decision, such as the size of your production runs, the types of materials you will be sealing, and your budget.

In this comprehensive guide, we will explore the important considerations you need to keep in mind when selecting a plastic tray sealing machine tailored to your specific needs. From understanding the different sealing technologies and machine features to evaluating maintenance requirements and supplier support, this article will empower you with the knowledge to make an informed choice. Whether you're in the food industry, pharmaceuticals, or any business that requires efficient packaging solutions, having the right plastic tray sealing machine can streamline your operations and elevate your brand's reputation in the marketplace.

Understanding Your Business Needs for Plastic Tray Sealing Machines

When selecting a plastic tray sealing machine for your business, it's essential to first assess your specific operational needs. Consider the types of products you will be sealing, whether it's food, electronics, or medical supplies, as different materials and sealing methods are suited for different applications. For food products, for instance, you may require a machine that adheres to safety standards and offers features such as vacuum sealing or modified atmosphere packaging to preserve freshness.

Another critical factor to evaluate is your production volume and speed requirements. Businesses with high output needs may benefit from an automatic sealing machine that can handle large batches efficiently, while smaller operations might find a manual or semi-automatic unit sufficient. Additionally, think about the available space in your facility; a compact model might be more appropriate if floor space is limited. By carefully analyzing these elements, you can choose a tray sealing machine that aligns with your business objectives and enhances your productivity.

Key Features to Look for in a Plastic Tray Sealing Machine

When selecting a plastic tray sealing machine for your business, it is essential to focus on key features that will enhance efficiency and sustainability. One of the primary aspects to consider is the machine's sealing capability, which should ensure a secure and consistent seal to maintain product freshness while minimizing waste. Additionally, the speed and capacity of the machine should align with your production demands, enabling you to meet market needs without sacrificing quality.

Another crucial feature is energy efficiency, which not only lowers operational costs but also supports sustainability goals. As the packaging industry increasingly shifts towards eco-friendly practices, investing in a machine that incorporates renewable or recycled materials can significantly enhance your brand's reputation. Furthermore, user-friendliness and ease of maintenance are vital for ensuring that your staff can operate the machine without extensive training, thereby reducing downtime and improving productivity. By focusing on these key features, businesses can make informed decisions that contribute to their growth in the rapidly evolving packaging market.

Assessing Size and Production Capacity Requirements

When selecting a plastic tray sealing machine, one of the most critical factors to consider is the size and production capacity that aligns with your business needs. According to a recent industry report by MarketsandMarkets, the global food packaging market is expected to reach over $500 billion by 2025, indicating a growing demand for efficient packaging solutions. This surge emphasizes the necessity of choosing a machine that can accommodate your current output while allowing for future growth.

The production capacity of your chosen machine depends on your operational scale. For small to medium-sized businesses, a machine with an output of around 10-20 trays per minute may suffice. In contrast, larger operations may require models capable of producing 30-50 trays per minute or more. A study conducted by Smithers Pira revealed that demand for automation in packaging processes is projected to increase by 15% annually, further highlighting the importance of investing in a tray sealing machine that can efficiently handle your desired volume while optimizing labor and material costs. Understanding your size requirements and future production goals is essential to making an informed decision that will support your business growth effectively.

How to Choose the Best Plastic Tray Sealing Machine for Your Business - Assessing Size and Production Capacity Requirements

| Feature | Value |

|---|---|

| Max Tray Size | 400 x 300 mm |

| Production Capacity | 600 trays/hour |

| Power Consumption | 2 kW |

| Seal Type | Heat Seal |

| Machine Dimensions | 1500 x 800 x 1200 mm |

| Weight | 250 kg |

| Material Compatibility | Plastic, Aluminium Foil |

| Control System | PLC with Touchscreen |

| Warranty | 1 Year |

Comparing Costs: Budgeting for Your Plastic Tray Sealer

When budgeting for a plastic tray sealing machine, it's crucial to consider not just the upfront purchase cost, but also the long-term operational expenses. According to industry reports, the initial investment for high-quality tray sealing machines can range from $5,000 to over $50,000, depending on features and production capacity. Additionally, annual maintenance and operating costs can average around 10-15% of the machine's purchase price, which emphasizes the importance of comprehensive budgeting.

Tips: Always factor in the cost of consumables like film and trays, which can affect your overall operating budget. Look for machines that offer compatibility with various materials to enhance flexibility and reduce costs.

Moreover, researching different suppliers and comparing warranty options can provide insights into hidden costs and help mitigate risks associated with equipment failure. Financial analysts recommend considering the total cost of ownership (TCO) approach, which evaluates purchase price alongside projected operating costs over the machine's lifespan. This approach reveals the true investment required and aids in making informed decisions that align with your business's financial strategy.

Tips: Utilize online calculators to estimate TCO based on your production needs and seek machine demonstrations to better assess performance before making a purchase.

Evaluating Manufacturer Support and Maintenance Services

When selecting a plastic tray sealing machine for your business, evaluating the manufacturer's support and maintenance services is crucial. A reliable support system ensures that any issues you encounter can be resolved quickly, minimizing downtime. Look for manufacturers who offer comprehensive service contracts, including regular maintenance visits, on-site troubleshooting, and prompt replacement of parts. This level of support not only keeps your machine running efficiently but also extends its operational lifespan, which is essential for maintaining production capacity.

Moreover, consider the availability of technical support resources such as online manuals, video tutorials, and customer service hotlines. A manufacturer that provides comprehensive training for your staff can significantly impact your operational efficiency. Effective communication with the manufacturer can also facilitate better outcomes when issues arise, as a responsive team will enhance your overall experience. Therefore, investing time in assessing the manufacturer's support and maintenance offerings can lead to better equipment performance and greater peace of mind for your business.

Comparison of Key Features in Plastic Tray Sealing Machines

Related Posts

-

The Ultimate Guide to Choosing the Right Plastic Tray Sealing Machine for Your Business

-

7 Essential Tips to Optimize Your Tray Sealer Packaging Machine Efficiency

-

How to Optimize Your Production Line with a Tray Sealer Packaging Machine

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process

-

How to Choose the Best Tray Packaging Machine for Your Business Needs

-

How to Optimize Blister Thermoforming for Maximum Efficiency and Cost Savings in Packaging