How to Choose the Right Blister Packaging Equipment for Your Business Needs

When it comes to packaging products efficiently and effectively, choosing the right blister packaging equipment is a crucial decision for any business. Blister packaging has become increasingly popular across various industries due to its ability to provide product protection, enhance shelf appeal, and streamline the packaging process. However, with a multitude of options available on the market, selecting the best equipment tailored to your specific needs can be daunting.

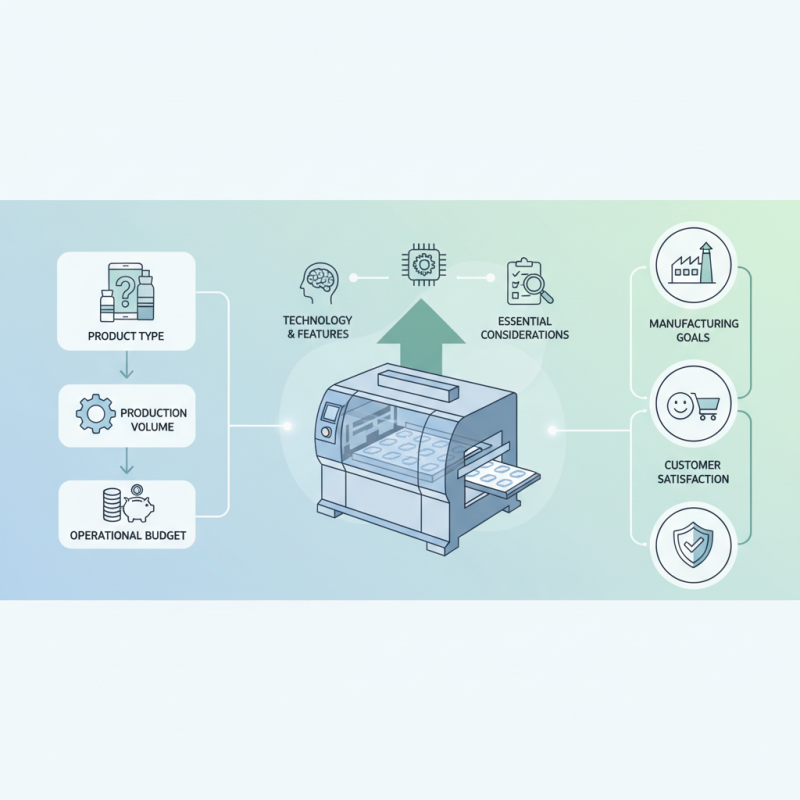

To navigate this complex landscape, businesses must consider several factors, including the type of products being packaged, production volume, and operational budget. Moreover, understanding the various technologies and features available within blister packaging equipment can help in making informed decisions that align with business requirements. This guide aims to provide insights into the essential considerations for choosing blister packaging equipment, ensuring that your investment supports both your manufacturing goals and customer satisfaction.

Understanding the Basics of Blister Packaging Equipment Choices

When selecting blister packaging equipment for your business, understanding the various types and their capabilities is crucial. Blister packaging, known for its efficiency in protecting products while providing visibility, comes in different formats—such as carded, heat-sealed, and peelable blisters. A 2021 report from Mordor Intelligence noted that the global blister packaging market is projected to grow at a compound annual growth rate (CAGR) of 5.67% from 2021 to 2026. This growth reflects the increasing demand for safe and convenient product packaging across various industries, including pharmaceuticals, consumer goods, and electronics.

Tips: Before making a decision, evaluate your specific packaging needs. Consider the materials you plan to use, the production volume, and the desired shelf life of your products. Investing in equipment that is versatile and capable of handling various materials can save costs in the long run and adapt to future changes in your product line.

Another vital aspect to consider is the automation level of the equipment. According to a study by Smithers, 70% of manufacturers are shifting towards automated blister packaging solutions to enhance efficiency and reduce labor costs. While fully automatic systems may require a larger initial investment, they can significantly increase productivity and minimize human error, delivering a better return on investment. Thus, choosing the right level of automation will depend on your production capacities and operational budget.

Key Factors Influencing Blister Packaging Equipment Selection

When selecting blister packaging equipment for your business, it's critical to consider several key factors to ensure it meets your operational needs. One of the most significant considerations is the type of product you are packaging. According to a report by Smithers Pira, the global blister packaging market is projected to reach $30.5 billion by 2026, driven by the growing demand in the pharmaceutical and consumer goods sectors. The characteristics of your product, such as size, shape, and sensitivity, will dictate the type of blister material and sealing technology to utilize.

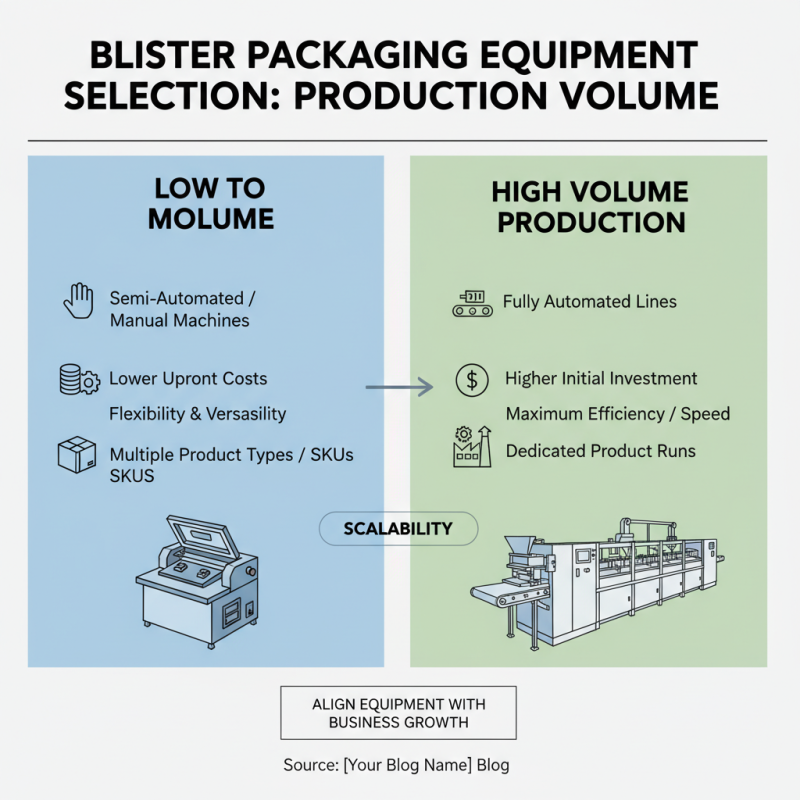

Another critical aspect is the production volume. If you're operating at a high volume, investing in automated blister packaging machines will enhance efficiency and reduce labor costs. A study from Research and Markets indicates that automated equipment can improve production rates by up to 40%, making it a worthwhile investment for large-scale operations. Conversely, for smaller operations or less frequent runs, semi-automatic models may be more appropriate.

**Tips:** Always factor in the potential for scalability. Choose equipment that can adapt to changing production demands without requiring a full replacement. Additionally, consider the ease of maintenance and availability of replacement parts, as both can impact long-term operational efficiency and costs.

How to Choose the Right Blister Packaging Equipment for Your Business Needs

| Criteria | Description | Impact |

|---|---|---|

| Production Volume | Assess the amount of product to be packaged. | High volume may require automated equipment. |

| Product Type | Different products may need specific features for packaging. | Influences the choice of materials and machine design. |

| Regulatory Compliance | Consider regulatory requirements for the product. | Compliance may require specific machine features. |

| Budget | Determine the budget available for equipment purchase. | Limits the options available for selection. |

| Ease of Use | Evaluate the user-friendliness of the equipment. | Affects training time and operational efficiency. |

| Maintenance Requirements | Consider how often the equipment needs maintenance. | Impacts production downtime and overall costs. |

Evaluating Production Volume: Matching Equipment to Needs

When selecting blister packaging equipment, evaluating your production volume is essential to ensure that the machinery aligns with your business requirements. The relationship between production volume and packaging efficiency cannot be overstated. Businesses with low to moderate output may benefit from semi-automated or manual blister sealing machines, which offer flexibility and lower upfront costs. These machines are often capable of accommodating various product types, making them suitable for smaller operations or those that produce multiple item lines.

On the other hand, companies with higher production demands should consider fully automated blister packaging systems. These machines offer faster processing speeds, continuous operation, and streamlined workflows, which help minimize labor costs and reduce the risk of production bottlenecks. It's crucial for businesses to analyze their projected growth and production needs over time, as investing in equipment that can scale with your operations will provide a significant return on investment. By matching the capacity of the blister packaging equipment to your specific production volume, you can optimize both efficiency and output, ultimately supporting your business's long-term success.

Types of Blister Packaging Equipment and Their Applications

Blister packaging equipment comes in various types, each tailored to specific applications and industries. The most common type is the flat blister machine, which is widely used in pharmaceuticals for packaging tablets and capsules. This machine creates a sealed plastic cavity for each unit dose, ensuring product integrity and protection from moisture and contamination. Its ability to handle high production rates and offer customizable blister sizes makes it a popular choice for manufacturers looking to improve efficiency.

Another type of blister packaging equipment is the thermoforming machine, which is ideal for products that require a more complex shape or design. This equipment forms the blister directly from a roll of plastic film, allowing for greater flexibility in terms of packaging size and depth. It is widely used in the food industry, where different items like consumables and utensils can be packaged securely and attractively. Additionally, skin packaging machinery is a notable variant that uses a thin film to closely conform to the product, making it perfect for consumer goods and electronics, providing visibility while protecting the items.

In conclusion, selecting the right blister packaging equipment greatly depends on the specific needs of your business. Understanding the various types and their applications can lead to improved packaging solutions that not only enhance product presentation but also ensure protection and compliance with industry standards.

Blister Packaging Equipment Types and Their Applications

Cost Considerations: Investment vs. Long-term Benefits in Blister Packaging

When considering blister packaging equipment, cost is a pivotal factor that can significantly influence your business's operational efficiency and bottom line. According to a report by Smithers Pira, the global blister packaging market is projected to grow by over 6% annually, emphasizing the increasing reliance on this packaging method for a variety of industries, from pharmaceuticals to consumer goods. This growth highlights the importance of not merely viewing the upfront investment as a cost but rather as a vital allocation of resources that can lead to improved productivity and reduced waste over time.

Investing in high-quality blister packaging equipment may initially seem daunting due to the upfront costs, which can range from tens of thousands to hundreds of thousands of dollars. However, industry studies suggest that businesses that opt for durable and technologically advanced machines experience a 15-20% reduction in packaging errors and waste. Additionally, the long-term benefits include faster production times and increased flexibility to adapt to market demands, often resulting in a lower cost-per-unit over the lifespan of the machinery. By weighing these long-term benefits against initial expenses, businesses can make informed decisions that align both with their financial plans and operational goals.

Related Posts

-

Revolutionizing Efficiency: How Thermoforming Blister Packaging Machines Boost Production by 30%

-

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs

-

Innovative Heat Sealing Machine for Blister Packaging Revolutionizes Industry Trends at 2025 China Import and Export Fair

-

Top 5 Blister Sealing Machines for Efficient Packaging Solutions

-

Understanding the Benefits of Tray Sealer Packaging Machines for Food Safety and Freshness

-

Unlocking the Future of Packaging Automation with Digital Innovations