How to Choose the Best Blister Pack Sealing Machine for Your Business Needs

When it comes to packaging products efficiently and securely, investing in the right blister pack sealing machine is crucial for any business. This type of machinery plays a vital role in various industries by ensuring that products are well-protected from external factors, thereby extending shelf life and providing an appealing presentation. However, choosing the best blister pack sealing machine requires careful consideration of multiple factors, including product specifications, production volume, and budget constraints.

Understanding the various features and capabilities of different sealing machines can significantly impact a company’s operational efficiency and profitability. A blister pack sealing machine should not only meet the specific needs of your products but also integrate seamlessly with existing production lines. Whether you are a small business looking to scale up or a larger enterprise streamlining packaging processes, evaluating the right machine can enhance productivity and ensure that your goods reach customers in pristine condition. This guide will provide you with the essential information needed to select the optimal blister pack sealing machine tailored to your business needs.

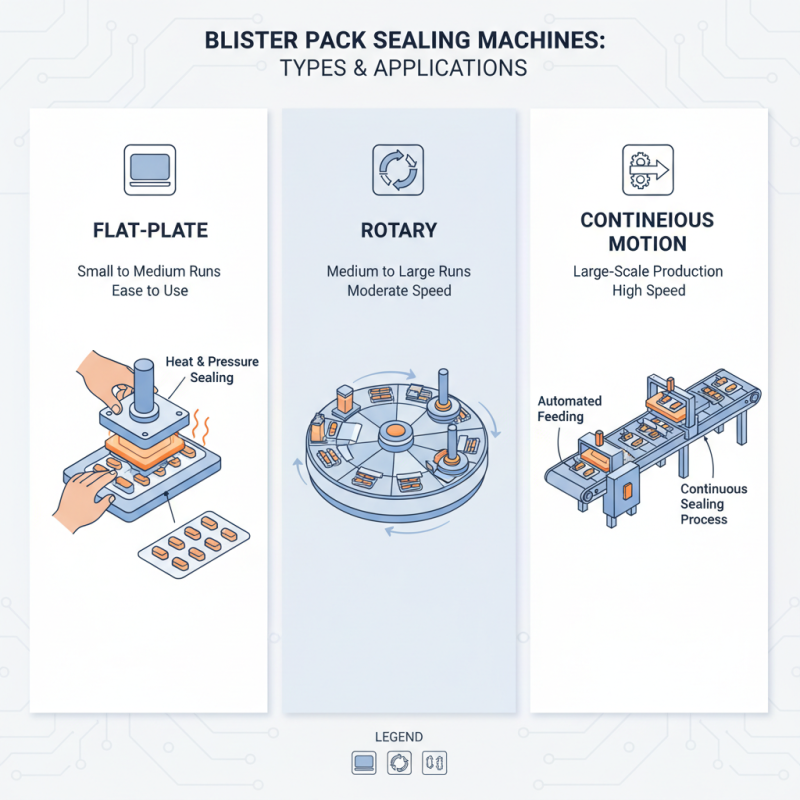

Understanding the Different Types of Blister Pack Sealing Machines

When selecting a blister pack sealing machine for your business, it is vital to understand the different types available. The most common categories include flat-plate, rotary, and continuous motion blister sealing machines. Flat-plate machines are ideal for small to medium production runs, offering ease of use and maintenance. They operate by placing the blister and backing material on a flat surface, where heat and pressure seal the pack together.

Rotary machines, on the other hand, are designed for high-volume production. They utilize a rotating mechanism that allows for quicker processing, making them suitable for industries that require large quantities of sealed blisters. Continuous motion machines combine speed and efficiency, continuously feeding material through the sealing process, which is essential for businesses looking to maximize output without compromising quality.

**Tips:** When choosing a blister pack sealing machine, consider your production volume and the types of products you are packaging. It’s also important to assess the size and design of the blisters you need, as well as the materials used in sealing. Don’t forget to evaluate the machine’s maintenance requirements and ease of operation to ensure seamless integration into your production line. Additionally, reviewing customer feedback and industry standards can provide valuable insights to help make the best choice for your needs.

Evaluating Your Business's Production Needs for Sealing Machines

When considering the selection of a blister pack sealing machine, it is crucial to assess your business's specific production needs. According to a recent report by Smithers Pira, the global blister packaging market is projected to reach $32.7 billion by 2025, driven by increased demand across sectors like pharmaceuticals and consumer goods. This surge in production necessitates that businesses closely evaluate their current and future output requirements, as well as regulatory compliance in their respective industries.

Moreover, understanding the scale of production is essential for choosing the right sealing machine. For instance, businesses aiming for high-volume production may benefit from machines that offer faster cycle times and enhanced automation features. A report from Technavio indicates that automated sealing machines improve operational efficiency by up to 30%, allowing businesses to meet increasing demand without compromising quality. Additionally, assessing the types of products being packaged and their sensitivity to environmental factors will further guide your decision in selecting a machine that aligns with your production needs.

Key Features to Look for in Blister Pack Sealing Equipment

When selecting a blister pack sealing machine for your business, it's crucial to focus on key features that cater to your specific operational needs. One of the primary considerations is the machine's sealing capacity. Depending on your production volume, you should look for a machine that can efficiently handle the desired output per hour while maintaining consistent quality in every seal. Additionally, adjustable sealing temperatures and times are essential features that allow for customization based on the materials used and the products being packaged.

Another important aspect to consider is the versatility of the sealing machine. A multifunctional machine that can accommodate various blister configurations and materials will enhance your production flexibility. This is particularly vital for companies that may need to switch between different product lines.

Furthermore, the ease of use and maintenance are critical factors; a user-friendly interface can reduce training time for operators, while simple maintenance protocols can minimize downtime, ensuring that your production line runs smoothly. Focus on machines that incorporate advanced technology for monitoring and diagnostics, as this can facilitate quicker adjustments and enhance overall efficiency.

Assessing Budget and Cost-Effectiveness for Your Sealing Machine

When selecting a blister pack sealing machine for your business, it's crucial to assess not just the machine's functionality but also the overall cost-effectiveness relative to your budget. According to a recent industry report from MarketsandMarkets, the blister packaging market is projected to reach USD 25.2 billion by 2025, emphasizing the need for efficient packaging solutions. A key factor in making a cost-effective decision is calculating the total cost of ownership (TCO), which includes initial purchase price, maintenance, operational costs, and the potential return on investment (ROI).

Tip: Before finalizing your choice, conduct a lifecycle cost analysis to understand the long-term financial implications. This will help you to compare different machines beyond just their upfront costs, giving you a clearer picture of their actual value over time.

Moreover, consider the scalability of your selected machine. If your business is expected to grow, investing in a machine that can handle increased production demands while maintaining efficiency can save you costs down the line. Industry insights indicate that automated blister packing machines can enhance production speed by up to 30%, significantly affecting labor costs and operational efficiency.

Tip: Invest time in understanding your current production volume and forecasting future needs. This knowledge will aid in selecting a sealing machine that not only fits your current financial plans but also aligns with your future growth strategy.

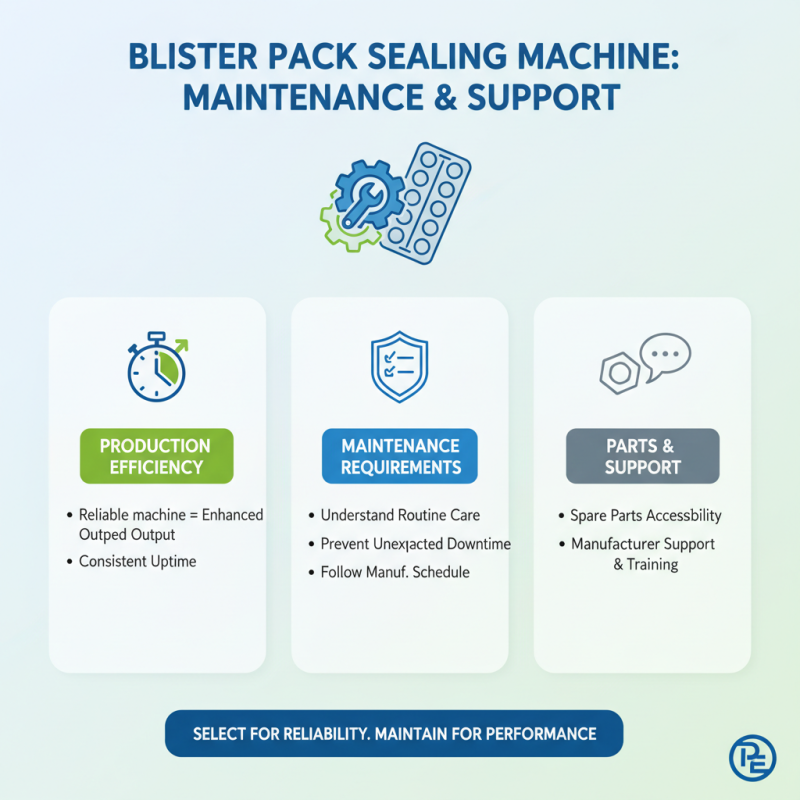

Maintenance and Support Considerations When Choosing a Machine

When selecting a blister pack sealing machine for your business, maintenance and support should be paramount in your decision-making process. A reliable sealing machine will not only enhance your production efficiency but also requires consistent maintenance to ensure optimal performance. Understanding the maintenance requirements of the machine you choose will help you avoid unexpected downtimes that can disrupt operations. Make sure to check the accessibility of spare parts and the manufacturer's recommendations for routine maintenance schedules.

Tips: Always ask for a maintenance manual and documentation detailing the machine's service history. This can provide insights into how often the machine requires maintenance and any common issues faced.

In addition to maintenance, consider the level of technical support provided by the manufacturer. A responsive support team can make a significant difference in keeping your production line running smoothly. Look for companies that offer comprehensive training sessions for your staff, along with ongoing technical support through various channels like phone or email.

Tips: Before finalizing your purchase, reach out to the support team with specific questions to gauge their responsiveness and ability to assist you post-purchase. This proactive approach can save time and trouble in the long run.

Related Posts

-

Best Heat Sealing Machine for Blister Packaging 2023 Top Choices for Your Packaging Needs

-

How to Optimize Blister Thermoforming for Maximum Efficiency and Cost Savings in Packaging

-

Exploring the Benefits of Investing in a High Quality Plastic Tray Sealing Machine

-

Innovative Examples of Packaging Equipment Transforming Global Supply Chains

-

Unlocking Efficiency: The Future of Blister Packaging Equipment in Modern Manufacturing

-

2025 Top Blister Pack Sealing Machine: Innovations & Best Practices