Innovative Techniques for Using the Best Nameplate Marking Machine

In today's fast-paced manufacturing environment, the need for precision and efficiency in identification processes has never been more critical. According to a recent report by Smithers Pira, the global market for marking machines is expected to reach $3.5 billion by 2025, driven by increasing demand for customized labels and nameplates across various industries. A Nameplate Marking Machine plays a pivotal role in this transformation, providing innovative solutions for sustainable marking that's both versatile and reliable. As businesses seek alternatives to traditional marking methods, exploring cutting-edge techniques becomes essential for maintaining competitive advantage and meeting regulatory standards. This blog will delve into innovative approaches utilizing the best Nameplate Marking Machines, highlighting their importance in enhancing product visibility and brand integrity.

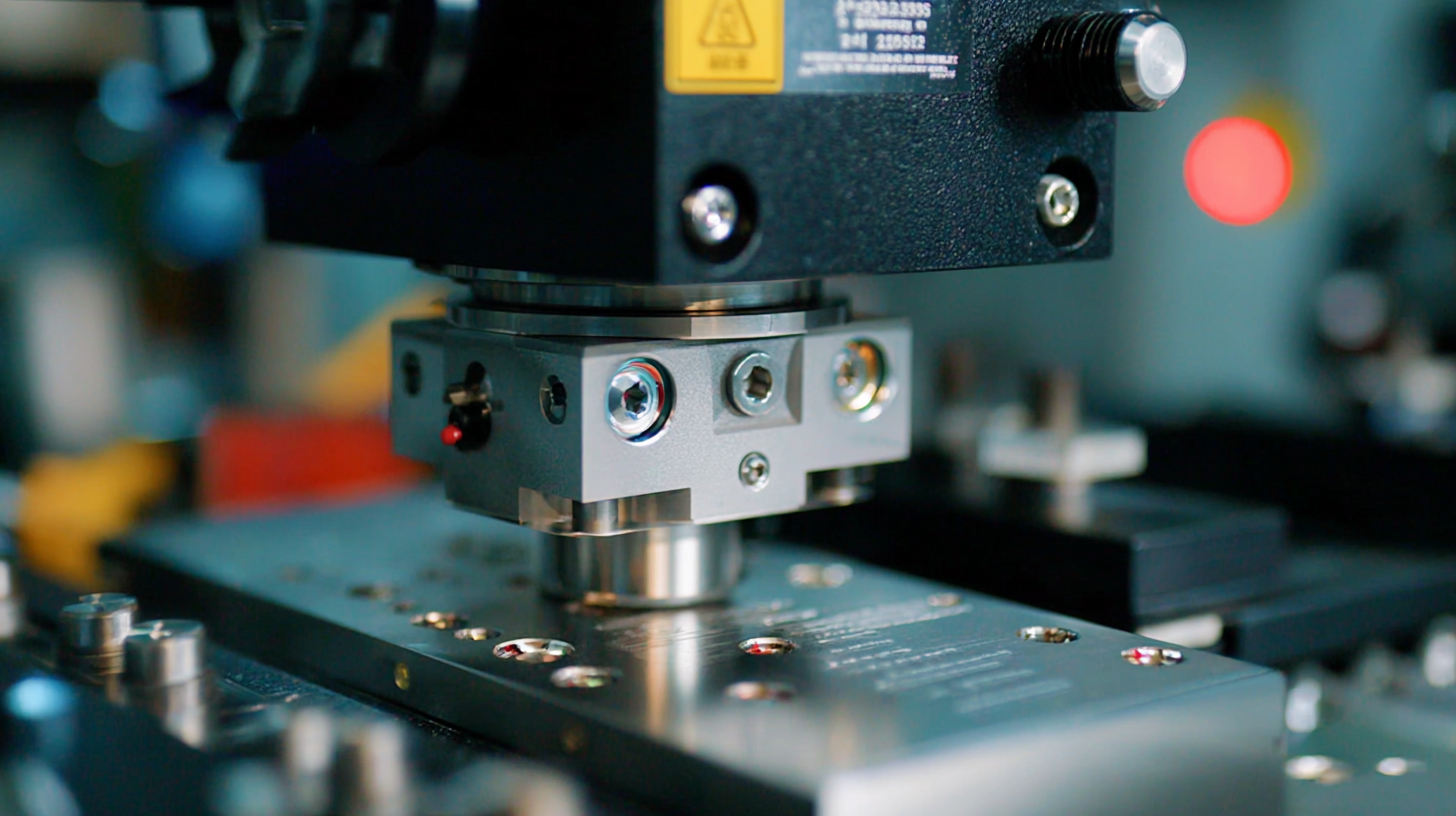

Innovative Features of 2025 Nameplate Marking Machines: What to Expect

As we look forward to 2025, nameplate marking machines are set to revolutionize the manufacturing and branding landscape with their innovative features. One of the most exciting advancements involves the integration of AI-driven technology. This feature not only enhances precision but also allows for real-time adjustments based on production demands. By utilizing machine learning algorithms, these machines can optimize marking parameters, ensure consistent quality, and reduce waste, enabling businesses to streamline their operations effectively.

Another noteworthy innovation is the incorporation of multi-functional capabilities within a single machine. The 2025 models are expected to offer a range of marking techniques, including laser engraving, dot peen marking, and thermal transfer printing. This versatility will allow manufacturers to cater to diverse materials and product requirements without the need for multiple devices, thus saving both time and resources. Additionally, the ease of use in these new models, characterized by intuitive interfaces and connectivity to cloud-based systems, will empower operators with enhanced control and monitoring capabilities, ensuring optimal performance throughout the marking process.

Impact of Automation on Nameplate Marking Efficiency in 2025

As we look ahead to 2025, the impact of automation on nameplate marking efficiency is becoming increasingly significant. With advancements in technology, businesses are now leveraging automated marking systems that streamline the production process. These systems not only enhance precision but also dramatically reduce the time required for each marking project. For instance, automated laser marking machines can perform intricate designs and text with speed and accuracy, eliminating the human error often associated with manual systems.

Moreover, the integration of automation into nameplate marking is facilitating greater customization. Companies can now easily adapt their production lines to meet specific client demands or create limited edition items with unique logos and designs. This flexibility is crucial in today's fast-paced market, where customer preferences can shift rapidly. As we advance, the use of artificial intelligence and machine learning in these processes will further optimize operations, paving the way for even more efficient and innovative marking solutions that cater to a variety of industrial needs.

Sustainability Trends in Nameplate Marking Technologies for the Future

Sustainability is becoming increasingly crucial in the nameplate marking industry, as companies seek environmentally friendly practices. A report by Smithers Pira highlights that the global market for sustainable labeling technologies is projected to grow by 4.5% annually, reaching $24.4 billion by 2025. This trend reflects a shift towards practices that reduce waste and improve efficiency in nameplate production. Manufacturers are now adopting eco-friendly materials, like biodegradable plastics and recycled metals, which not only satisfy consumer demand but also comply with stringent regulations surrounding sustainability.

In addition, advancements in marking technologies further enhance sustainability efforts. Laser marking, for example, offers a solvent-free solution that minimizes emissions and waste compared to traditional ink-based methods. According to a recent study by Freedonia Group, laser technologies are expected to see a growth rate of over 6% by 2024, indicating a robust shift towards sustainable practices. As businesses integrate these innovative techniques into their operations, they are not only improving their environmental footprint but also setting a standard for future developments in nameplate marking technologies.

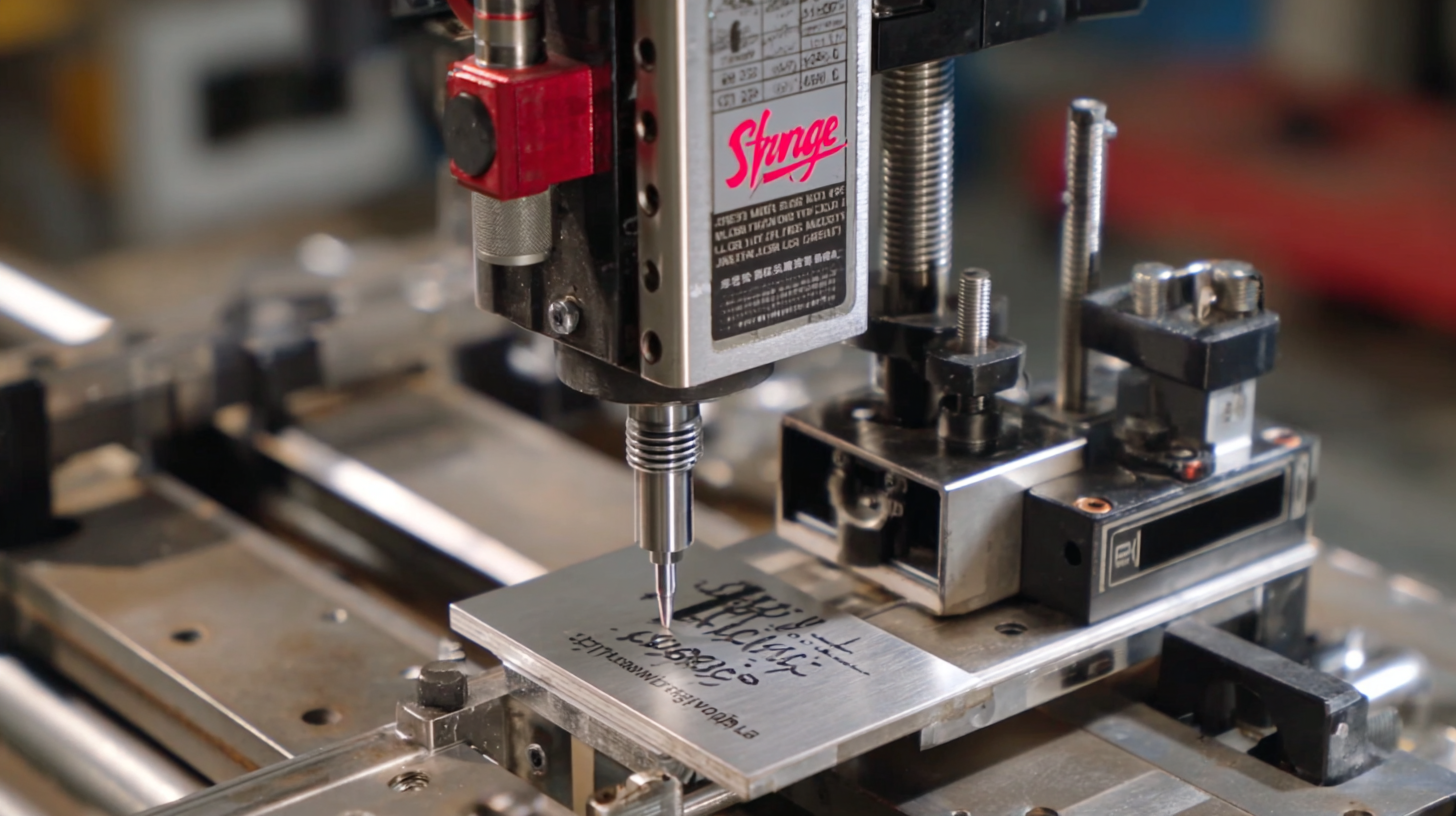

Comparative Analysis: Laser vs. Impact Marking Techniques in 2025

In 2025, the laser processing market is expected to reach a valuation of USD 7.17 billion, with projections indicating a rise to USD 11.89 billion by 2032. This growth, attributed to a compound annual growth rate (CAGR) of 8.5%, reflects the increasing adoption of laser marking technologies across various industries. Compared to traditional impact marking techniques, laser marking offers significant advantages, including precision, speed, and versatility in material applications. This makes it an ideal choice for creating high-quality nameplates that demand durability and detail.

A comparative analysis of laser versus impact marking techniques reveals distinct operational efficiencies. Laser marking stands out in applications involving intricate designs or text, as it can maintain clarity and precision on diverse substrates like metals and plastics. Moreover, advancements in laser technology have led to innovative methods, such as Laser Polymer Tattooing (LPT), which promise to enhance the marking process on even challenging materials, such as polyoxymethylene. As industries continue to seek out more efficient and reliable marking solutions, the scalability and precision of laser techniques position them as a leading choice in the marking machine market.

Innovative Techniques for Using the Best Nameplate Marking Machine - Comparative Analysis: Laser vs. Impact Marking Techniques in 2025

| Feature | Laser Marking | Impact Marking |

|---|---|---|

| Precision | High (0.01 mm) | Moderate (0.1 mm) |

| Speed | Fast (up to 300 mm/sec) | Slow (up to 50 mm/sec) |

| Material Compatibility | Metals, plastics, ceramics | Metals, hard materials |

| Cost | Higher initial investment | Lower initial investment |

| Maintenance | Low | Moderate |

| Environmental Impact | Lower emissions | Higher emissions |

Cost-Benefit Analysis: Investing in Advanced Nameplate Marking Solutions

Investing in advanced nameplate marking solutions can yield significant returns by enhancing efficiency and ensuring accuracy in manufacturing processes. According to a recent report by MarketsandMarkets, the global nameplate marking machine market is expected to grow at a CAGR of 5.2% from 2023 to 2028. This growth reflects the increased demand for durable and precise marking methods in industries like automotive, electronics, and consumer goods. By deploying state-of-the-art marking machines, companies can reduce error rates and improve their production timelines, ultimately driving down costs in the long run.

**Tip:** Consider analyzing the total cost of ownership (TCO) of traditional versus advanced marking solutions. While advanced machines may have a higher upfront cost, their longevity and efficiency improvements often lead to lower operational costs over time.

Furthermore, advanced machines feature innovative technologies such as laser marking, which offers unmatched precision and can handle a variety of materials without the need for ink or solvents. The 2022 Industrial Machinery Survey revealed that businesses relying on laser marking reported a 30% increase in productivity compared to those using traditional methods.

**Tip:** Ensure that you assess the scalability of the marking solutions. Select machines that can grow with your production needs, providing flexibility in marking more complex designs as your business evolves.