Unlocking the Secrets of Blister Tooling: A Comprehensive Guide to Efficient Packaging Solutions

In the ever-evolving landscape of packaging solutions, blister tooling has emerged as a vital component for manufacturers seeking efficiency and cost-effectiveness. As highlighted in the recent Market Research Future report, the global blister packaging market is poised to reach approximately $35 billion by 2025, with blister tooling playing a crucial role in meeting the increasing demand for sustainable and user-friendly packaging. With advancements in materials and technology, businesses can now leverage innovative blister tooling strategies to enhance product protection and shelf appeal. This comprehensive guide aims to unlock the secrets of blister tooling, providing insights into best practices and cutting-edge techniques that can help companies streamline their packaging processes and achieve a competitive edge in the market.

Understanding Blister Tooling: Types and Their Applications in Packaging

Blister tooling is a pivotal aspect of packaging that plays a crucial role in the protection and presentation of products. Various types of blister tooling exist, each suited for different applications. The most common types include carded blisters, which are ideal for retail packaging, and clamshells that provide robust protection for a range of consumer goods. Additionally, there are bubble packs designed for smaller items that require minimal packaging, ensuring a balance between safety and product visibility.

Understanding the applications of these different blister tooling types is essential for manufacturers and retailers alike. Carded blisters enhance shelf appeal by allowing consumers to view the product while ensuring security against tampering. In contrast, clamshells offer extensive protection during transit, making them suitable for fragile items. By selecting the appropriate blister type, businesses can optimize their packaging strategy, enhance product visibility, and improve overall customer experience.

Key Materials Used in Blister Tooling: Assessing Durability and Cost-Effectiveness

Blister tooling plays a crucial role in the packaging industry, especially for products that require protection and visibility. The materials used in blister tooling significantly influence both durability and cost-effectiveness. Common materials include PVC, PET, and APET, each presenting unique benefits and challenges. PVC, for instance, is favored for its excellent clarity and formability, making it ideal for retail packaging. However, its environmental impact raises concerns, prompting manufacturers to explore more sustainable alternatives.

PET and APET have gained popularity due to their recyclability and favorable mechanical properties. These materials offer a good balance between strength and cost, making them suitable for a wide range of applications, from pharmaceuticals to consumer goods. When assessing durability, factors such as thickness, impact resistance, and barrier properties must be considered. Ultimately, selecting the right material in blister tooling not only enhances product safety but also aligns with economic and environmental goals, paving the way for innovative and efficient packaging solutions.

The Role of Automation in Blister Packaging: Increasing Efficiency and Reducing Waste

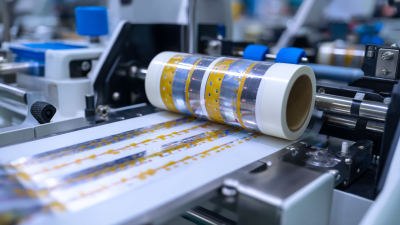

Automation has revolutionized the blister packaging industry, enhancing efficiency and significantly reducing waste. By integrating sophisticated machinery and software into the packaging process, manufacturers can achieve higher precision and speed. Automated blister tooling not only streamlines production lines but also minimizes human error, which can lead to costly defects and material wastage. With the ability to adjust parameters in real-time, automated systems ensure that each package is produced to exact specifications, further optimizing the use of materials.

In addition to improving productivity, the role of automation in blister packaging is crucial for sustainability. Automated processes can accurately control the amount of packaging materials used, taking into account the specific requirements of each product. This capability helps to minimize excess packaging and dispose of surplus efficiently. Moreover, many modern automated systems are designed to recycle waste directly, further reducing the environmental impact of packaging operations. As companies continue to embrace automation, they not only enhance their operational efficiency but also contribute to a more sustainable future in packaging solutions.

Market Trends in Blister Packaging: Growth Projections and Technological Innovations

The blister packaging market has been witnessing significant growth driven by various technological innovations and increasing demand across multiple sectors. Recent projections indicate that the global cold form blister packaging market is expected to grow from $4.88 billion in 2025 to $6.64 billion by 2032, with a compound annual growth rate (CAGR) of 4.51%. This trend highlights the rising need for efficient packaging solutions that offer enhanced barrier properties, particularly in the pharmaceutical and food industries.

**Tips for Optimizing Blister Packaging:**

1. **Materials Matter:** When selecting materials for blister packaging, consider options that offer superior protection against moisture and oxygen to prolong product shelf life.

2. **Customization is Key:** Tailoring the blister design to align with consumer preferences can enhance branding efforts while ensuring user-friendly access to products.

In addition, the global pharmaceutical glass packaging market is anticipated to grow substantially, reaching over $100.76 billion by 2027, reflecting a CAGR of 6.3% during the forecast period. This growth underscores the essential role of innovative packaging in maintaining drug efficacy and safety. As the market expands, businesses must stay aligned with emerging trends to meet consumer demands effectively.

Market Trends in Blister Packaging: Growth Projections and Technological Innovations

This chart illustrates the market trends in blister packaging, showing growth projections from 2019 to 2025. The increasing demand for efficient packaging solutions is reflected in the rising market size, driven by innovations and advancements in blister tooling technologies.

Sustainability in Blister Tooling: Eco-Friendly Materials and Practices in the Industry

In the realm of blister tooling, sustainability has emerged as a crucial focus for manufacturers seeking to reduce their environmental impact. The industry is now prioritizing the use of eco-friendly materials, such as biodegradable plastics and recyclable substrates, which not only fulfill packaging requirements but also address ecological concerns. By opting for these materials, companies can significantly minimize their carbon footprint and contribute to a circular economy.

Additionally, sustainable practices in blister tooling extend beyond material selection. Innovations in production processes are helping to reduce waste and energy consumption. Techniques such as optimized layout design and energy-efficient machinery allow manufacturers to streamline their operations, leading to lower operational costs and environmental implications. Moreover, the adoption of life cycle assessments ensures that the sustainability of packaging solutions is evaluated at every stage, from material sourcing to end-of-life disposal, ensuring a more holistic approach to eco-friendly practices in the industry.

Related Posts

-

Blister Tooling Innovations Showcased at China's 138th Canton Fair in 2025 Driving Industry Growth

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

How to Optimize Blister Thermoforming for Maximum Efficiency and Cost Savings in Packaging

-

How to Optimize Blister Tray Packaging for Maximum Product Protection and Cost Efficiency

-

The Ultimate Guide to Choosing Eco-Friendly Pet Blister Packaging for Your Business

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process